- 1World class Solvent Extraction Plant Technology @ Most Economical Price.

- 2Eco Friendly and Lowest Water Discharge.

- 3Best Backup by Research and Development.

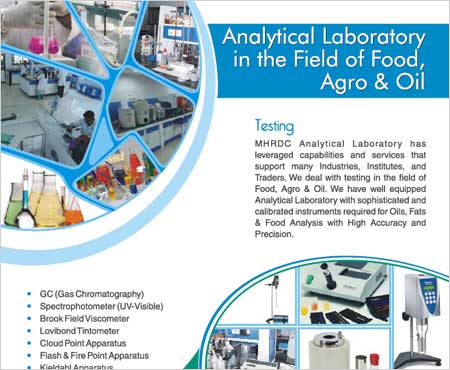

- 4Best Optimization for Quality & Maximum Quantity.

- 5Steam Conservation by Closed Loop Process.

- 6In House Manufacturing facility and third party Inspection.

- 7Maximum Energy Saving & Heat Recovery System.

- 8Best Instrumentation for Most Efficient and Operator Friendly Plant Operation.

- 9Quality Assurance directly by Muez-Hest R & D Team.

- 10A Global provider Of Highly Engineered Products.

Technologies Edible Oil Refinery Plant Manufacturers & Suppliers

Edible Oil Refinery Plant Manufacturers & Suppliers

What Is Edible Oil Refining

Edible oil refining is a vital process in producing edible oils and is conducted in specialized Edible Oil Refining plants. This process enhances the quality of crude oil extracted from seeds or fruits by removing impurities. Key stages include degumming, neutralization, bleaching, and deodorization. The aim is to produce refined oil with improved taste, smell, and nutritional value, meeting quality standards for consumption. Edible Oil Refining plants use advanced technologies to ensure the final product aligns with regulatory requirements and consumer expectations.

Muez-Hest is a technology development and EPC with a large part of our expertise pertaining to Edible Oil Refinery Plant Manufacturers & Suppliers.

Edible Oil Refinery Plant requires precision of machinery while ensuring minimum addition of contaminants and odour producing agents.

Muez-Hest has worked tirelessly with many customers in India and abroad developing fully customized solutions for their Edible Oil Refinery needs. We have developed equipment for all processes pertaining to edible oil refining plant such as:

Why Choose Muez Hest as India's Best Edible Oil Refinery Plant Manufacturers?

Selecting Muez-Hest as the preferred edible oil manufacturing company and edible oil refinery plant manufacturer in India is a strategic decision driven by a commitment to quality, expertise, and innovation. Recognized as a leading player in the industry, Muez-Hest has established a robust legacy with a global footprint, earning trust as a reliable partner in the edible oil manufacturing sector.

As an esteemed edible oil plant and equipment manufacturing company, Muez-Hest brings a wealth of experience to the table, having successfully executed numerous projects worldwide. Their standing as reputable edible oil refinery plant manufacturers underscores their expertise and reliability in delivering tailored solutions that meet clients' diverse needs.

Muez-Hest's dedication to quality is evident in the meticulous design of its edible oil refinery plants. These plants, crafted with precision, adhere to the highest efficiency standards, ensuring top-tier product quality—a critical factor in the competitive landscape of edible oil manufacturing.

The client-centric approach of Muez-Hest further distinguishes them in the industry. Recognizing the nuances of edible oil manufacturing, the company ensures that its edible oil refinery plants can be customized to align with each client's unique requirements, showcasing a commitment to meeting specific needs.

At the forefront of technological advancement, Muez-Hest incorporates state-of-the-art solutions in their edible oil refinery plants. This commitment to innovation ensures that clients benefit from cutting-edge features, enhancing overall efficiency and performance in edible oil refining.

One of the key differentiators for Muez-Hest is their unwavering commitment to sustainability and environmentally responsible practices. As a responsible edible oil refining technology provider and equipment manufacturing company, they prioritize R & D-based solutions for eco-friendly approaches, catering to clients who value sustainable business practices.

In the competitive landscape of edible oil manufacturing, cost-effectiveness is paramount. Muez-Hest not only delivers superior performance but also optimizes costs, providing clients with a competitive edge in the market.

Choosing Muez-Hest as the preferred edible oil manufacturing company and edible oil refinery plant manufacturer means aligning with a dedicated team committed to client success. With decades of experience and a focus on innovations and providing research-based solutions, Muez-Hest stands as a reliable and forward-thinking partner in the dynamic and evolving field of edible oil production.

Process Description of Edible Oil Refinery Plant

Degumming Process:-

Degumming Process:-

Water degumming is vital in Edible Oil Refining at a refinery plant. This process targets the removal of phospholipids, or gums, from crude vegetable oils, which can cause haze and off-flavors. In water degumming, water is added to the crude oil, causing the phospholipids to hydrate and form a sludge. The oil is then separated from the sludge through settling or centrifugation. This method effectively eliminates phospholipids, enhancing the quality and stability of edible oils. Water degumming is often part of a comprehensive refining process that includes neutralization, bleaching, and deodorization to produce high-quality edible oils.

Muez Hest also offers enzymatic degumming technology, which was developed by IICT (Indian Institute Of Chemical Technology) Hyderabad. A subsidiary of CSIR (Council of Scientific and Industrial Research) under TMOP and M (Technology Mission of Oilseed, Pulses, and Maize) Ministry of Agriculture, Govt. Of India.

Alkali Refining of Oil:-

Alkali Refining of Oil:-

Alkali refining, a pivotal step in edible oil manufacturing at a refinery plant, involves neutralizing crude oil with sodium hydroxide to remove free fatty acids and impurities. This process forms soap, which is separated through settling or centrifugation. The result is improved taste, color, and stability in the final edible oil product. Alkali refining is a crucial component of the overall edible oil refining process, addressing acidity and removing undesirable compounds before subsequent steps like bleaching and deodorization further enhance the oil's quality.

Bleaching Process in a Bleaching Plant:-

Bleaching Process in a Bleaching Plant:-

A Bleaching Plant is a vital component in the edible oil refining process within an Edible Oil Refinery Plant. It employs adsorbent materials like bleaching earth or activated carbon to selectively remove impurities, including pigments and residual soap, enhancing the color and purity of the oil. The process involves mixing, heating, and filtration, producing a clearer and refined oil. This crucial step in the edible oil manufacturing process contributes to improved appearance, flavor, and overall quality of the final product. The bleaching plant is typically part of a comprehensive refining process that includes degumming, neutralization, deodorization, and dewaxing.

Deodorization Process in a Deodorization Plant:-

Deodorization Process in a Deodorization Plant:-

A Deodorization Plant is a vital element in the edible oil refining process within an Edible Oil Refinery Plant. Using high-temperature steam removes unwanted odors and flavors from the oil. A vacuum system aids in minimizing thermal damage. The deodorized oil undergoes final filtration, producing a clear, odor-free, flavor-neutral product. This essential step enhances the sensory characteristics and stability of the oil, ensuring it meets industry standards and consumer expectations for high-quality edible oils. The Deodorization Plant is typically integrated into a comprehensive refining process, including degumming, neutralization, and bleaching.

Dewaxing/Winterization of Oil (if required):-

Dewaxing/Winterization of Oil (if required):-

Dewaxing/Winterization is a critical process in the production of edible oils at an Edible Oil Refinery Plant. It involves cooling crude oil to solidify waxes or hard fractions, which are then separated through filtration or centrifugation. This ensures the oil remains transparent and liquid even at lower temperatures, preventing cloudiness or sedimentation. Dewaxing/Winterization is particularly important for oils exposed to colder conditions during storage or use. Integrated into the broader edible oil refining process, it complements steps like degumming, neutralization, bleaching, and deodorization to produce high-quality, stable edible oils that meet industry standards and consumer expectations.

Dewaxing Crystallization Process Flow Diagram

Dewaxing Crystallization Process Flow Diagram Dewaxing Filtration Process Flow Diagram

Dewaxing Filtration Process Flow Diagram

Physical Refining :-

Physical Refining :-

Next step in Edible Oil Refinery is the Physical Refining method is employed to get rid of free fatty acid using Steam Distillation technique at warm temperature and under high vacuum and it is followed by Deodorization and an extra technical facility is else before deodorization for removal of free fatty acid.

Fractionation :-

Fractionation :-

Next step in Edible Oil Refinery is the Fractionation Plant MUEZ-HEST' is specialized to supply provide a low operating cost fractionation plant, which provides high Olein/soft Stearin yields at established management. We offer PLC (automation) for efficient working and reliability of the fractionation plant.

The separation of stearin & olein is continuously done on rotary vacuum drum filter / plate and frame filter and its principle is easy, whereas crystallization method involves an executive technique to develop and grow the particles size for simple & swish separation of stearin & olein.

Our technique ensures you a perfect technology.

Edible Oil Refinery Process Flow Diagram

Edible Oil Refinery Process Flow Diagram

Application: Vegetable Oil, Palm Oil, Sunflower Oil, Cottonseed Oil, Soybean Oil, Groundnut Oil, Ricebran Oil & Mustard Oil and many more.

Global Edible Oil Refining Plant Installations : India, United States of America, Peru, Argentina, Spain, Egypt, Burkino Faso, Nigeria, Mozambique, United Arab Emirates, Uzbekistan, Russia, Sri Lanka & Bangladesh.

Edible Oil Refining Plant Video

Edible Oil Refinery Plant Images

Why Choose Muez-Hest?

- 11We Have Experience More Than 270 Project.

- 12Muez-Hest one of the Leaders in Indian Market.

- 13Large Customer and Global Installations.

- 14Strong Brand Recognition.

- 15Complete customer satisfaction and To achieve minimum customer complaint.

- 16Continual improvement of quality.

- 17Contribution to industry by supplying superior products at best possible rate and earliest time.

- 18Strong track record for "On Time Delivery" and completion of projects.

- 19Higher Quality Assurance of Products.

- 20To Know More Advantage Muez-Hest